Collection: Nuclear Industry

E-Work's products and solutions are suitable for all pipe end preparation applications in the nuclear industry.

The piping system is an essential part of the functioning of a nuclear power plant and is formed by the circulation of water and steam through the plant. The average nuclear power plant has more than seven miles of piping inside it, a large amount of which requires construction and maintenance. The environment in which these pipes must operate is extremely corrosive and hostile to the materials due to the continuous high pressures and temperatures. Additionally, many nuclear power plants are located on the coast and use seawater for cooling, which in turn requires special pipes that can withstand the highly corrosive properties of saltwater. Therefore, the pipes must be made of high-grade steel such as stainless steel and nickel alloy pipes. The use of angle grinders or flame cutting torches for cutting and beveling these pipe materials is not recommended.

Practice has proved that the mechanical cutting of steel pipes and the welding preparation of pipe ends greatly affect the quality of welded joints, which is crucial to the safety of nuclear power plants.For thick-walled pipe welding applications and orbital pipe welding technology, welding engineers now require mechanized weld preparation for perfect and effective weld preparation during pipe welding.

-

Tube End Squaring Machine SD 4.5

Regular price $2,599.00 USDRegular priceUnit price / per$2,899.00 USDSale price $2,599.00 USDSale -

Orbital Pipe Saw Cutter R4

Regular price $2,499.00 USDRegular priceUnit price / per$2,999.00 USDSale price $2,499.00 USDSale -

Tube to Tubesheet Welding Machine MWP-65C + Power Supply MWA-400

Regular price $17,999.00 USDRegular priceUnit price / per$20,999.00 USDSale price $17,999.00 USDSale -

Tube to Tubesheet Welding Machine MWP-65 + Power Supply MWA-400

Regular price $13,210.00 USDRegular priceUnit price / per$18,999.00 USDSale price $13,210.00 USDSale -

Tube to Tubesheet Welding Machine MWP-38 + Power Supply MWA-200

Regular price $10,385.00 USDRegular priceUnit price / per$14,999.00 USDSale price $10,385.00 USDSale -

Open-head Orbital Welding Machine MWG-90 + Power Supply MWA-400

Regular price $17,000.00 USDRegular priceUnit price / per$25,998.00 USDSale price $17,000.00 USDSale -

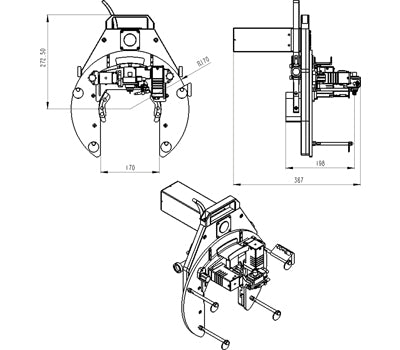

Open-head Orbital Welding Machine MWG-48 + Power Supply MWA-400

Regular price $33,798.00 USDRegular priceUnit price / per$41,998.00 USDSale price $33,798.00 USDSale -

Open-head Orbital Welding Machine MWG-325 + Power Supply MWA-400

Regular price $28,320.00 USDRegular priceUnit price / per$41,998.00 USDSale price $28,320.00 USDSale -

Open-head Orbital Welding Machine MWG-230 + Power Supply MWA-400

Regular price $27,380.00 USDRegular priceUnit price / per$38,998.00 USDSale price $27,380.00 USDSale -

Open-head Orbital Welding Machine MWG-170 + Power Supply MWA-400

Regular price $19,825.00 USDRegular priceUnit price / per$31,998.00 USDSale price $19,825.00 USDSale -

Closed-head Orbital Welding Machine MWF-80 + Power Supply MWA-200

Regular price $8,500.00 USDRegular priceUnit price / per$12,998.00 USDSale price $8,500.00 USDSale -

Closed-head Orbital Welding Machine MWF-40 + Power Supply MWA-200

Regular price $8,400.00 USDRegular priceUnit price / per$12,998.00 USDSale price $8,400.00 USDSale